Add to Cart

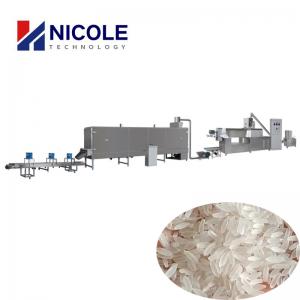

Fully Automatic Nutrition Artificial Fortified Rice Kernel Production Line Making Machine

Production Introduction:

The Fully Automatic Nutrition Artificial Fortified Rice Kernel Production Line Making Machine mainly adopts twin-screw extrusion technology, to produce nutritionally fortified rice. At the same time, various nutrients necessary for human health, such as vitamins, minerals and dietary fibers, can be added in proportion. This processing technology not only retains the original ingredients of ordinary rice, but also supplements and strengthens the human body lost due to finishing rice. Nutrients necessary for health; coarse grains can also be used to produce multi-grain rice.

Raw Materials:

The main raw materials are grain or grain powder, such as: rice flour, corn flour, bitter buckwheat flour, kudzu root powder and purple potato powder etc.

Flow Chart:

Mixing - Extruding - Drying - Cooling - Packing

Machine Details:

Machine Features:

1. All food contacted parts of are made of stainless steel.

2. The final products shapes and sizes can be various by changing the moulds and adjusting the speed of cutter.

3. Raw materials for the production line are broken rice or grain powder, which are easy to get.

4. We can customize the production line according to your exact requirements.

5. Use high-quality stainless steel to ensure the final products clean and hygienic.

6. The screw has a self-cleaning function, no need to disassemble the screw to clean up when the machine is stopped, and it is easy to maintain.

Photos of Samples:

Technical Parameter:

| Model | NT - 70 | NT - 75 |

| Installed Power | 100kw | 130 |

| Power Consumption | 60kw | 105 |

| Production Capacity | 200kg/h | 300kg/h |

| Dimension(LxWxH) | 18x2x3.5m | 25x2x3.5m |

Company Information:

Shandong Nicole Technology Co., Ltd. is a professional supplier of food processing machines, including industrial microwave dryer, hot air dryer, fruits & vegetables washing and cleaning machine, vacuum packing machine, frying machine, sterilizing machine, pet food/ fish feed production line, puffed snacks production line, artificial rice production line, pasta macaroni production line and so on.

Certifications:

Customers & Clients:

Our Service:

FAQ:

1. What is the payment terms?

Answer: We accept 30% T/T as deposit and the balance by T/T before shipping. We can also accept L/C, D/A, D/P, T/T, Western Union, MoneyGram etc. based on different orders.

2. Are you a manufacturer or a trader?

Answer: We are a manufacturer. We can manufacture the machines according to your exact requirements. And we supply OEM & ODM service.

3. Will you dispatch engineers to our factory for installation or training?

Answer: Yes, we can arrange our engineers to customers’ factories for installation and training, and we will calculate all the cost to customers. If you have your own engineers team, we can supply you manual book and guide video, keep 24 hours online to cooperate your engineers to finish the installation and operation.

Any interests, contact me for more details!